Raptor® Cleaning System

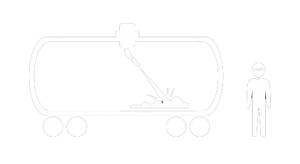

Designed and engineered to remove the most difficult products within minutes without the need for human entry, a Raptor® Cleaning System is the safest, most efficient, and economical heel removal and cleaning system for railcars on the market!

Safe

No Human Entry

Handles Hazardous Material

Efficient

Touchscreen Controls

Removes Heel in Minutes

Economic

Minimal Labor

Performance Guarantee

Integrated

Unified Equipment

Redundant Safeguards

Safe

Confined space tank entry cleaning is dangerous and expensive. Utilizing robotics and automation, the Raptor® Tank Cleaning System eliminates the need for human entry and harsh dig-out methods that require the use of shovels, picks, and handheld pressure washers. Not only does Raptor® Tank Cleaning eliminate employee’s exposure to hazardous environments and materials, it minimizes damage to railcars and can be used on all types of tanks, including rubber lined and painted. It is designed to quickly and safely remove heel from acid, asphalt, crude oil, vegetable oil, animal fat, and most products that require dig-out.

Efficient

Designed with end-users in mind, Raptor® Tank Cleaning System has a powerful yet simple to use software that enables programming of specific cleaning procedures and processes for different railcar types and products to ensure consistently cleaned tanks. Touch screen controls increase operator productivity by allowing them to easily control and monitor the system from a handheld device such as a tablet or smart phone, while they complete other tasks. The Raptor® Tank Cleaning System’s software also allows management to monitor station activity to improve overall through-put and scheduling.

Raptor® Tank Cleaning System utilizes the Bottom Outlet Valve (BOV) which makes for simple containerization to ensure easy, safe, and efficient transfer and disposal of the heel and cleaning solution.

Economical

Whether you are looking for a fixed base or mobile system, Raptor® Cleaning Systems can be designed and engineered as a complete turn-key solution or integrated to capitalize on your existing infrastructure and operation. Built with IP69K Food Grade Stainless Steel, the Raptor® Tank Cleaning System wash head is durable, eliminating maintenance costs and downtime that is associated with traditional spinner-jet systems. Regardless of which options you choose the typical return on investment (ROI) is very quick and our Raptor® system is guaranteed to meet your requirements!

Integrated

Utilizing Robotics, Automation and Technology, it is as easy as the push of a button to start a Raptor® Cleaning system. Whether it is a single component wash or a multiple component wash cycle, the pumps, wash-head and valves are integrated and programmed to automatically turn on and off removing the need for operator management. In addition, temperature and pressure sensors are strategically located throughout the system to eliminate damage to the railcar and Raptor® system components.

Raptor® systems design and engineer the components of each system to ensure compatibility and compliance to work as a system. We don’t just sell the equipment, we ensure it works together as a Safe, Effective and Efficient cleaning system. From Robotic Wash Heads and Control Cabinets to Pumps and Piping along with Platforms, Rail Track, Steam Boilers, Air Compressors, Pressure Washers, Buildings and Concrete, we can provide and install it.

Facility Construction

Raptor® doesn't just provide equipment; we create entire facilities from the ground up. Starting from a greenfield, we design and build the complete infrastructure needed for a fully operational cleaning facility. Our expertise encompasses all aspects of each project, including site preparation, building construction, and the installation of all Raptor® systems and support equipment. This turnkey approach ensures that your facility is ready to operate safely and efficiently from day one.

<img class="wp-image-807 size-large" src="https://www.raptortank.com/wp-content/uploads/2025/11/IMG_9444.jpg" alt="dirty railcar tank before heel removal" width="640" height="278" />

<img class="wp-image-807 size-large" src="https://www.raptortank.com/wp-content/uploads/2025/11/IMG_1457.jpg" alt="dirty railcar tank before heel removal" width="640" height="278" />

Sustainability of the Raptor Tank Cleaning system

Sustainability

The Raptor® Tank Cleaning system has the unique ability to utilize the tank’s original liquid as cleaning solution. This environmentally friendly and cost-effective option minimizes and often eliminates the need for cleaning chemicals and their costly disposal. Reclaimed product can be reused or recycled.

Raptor® Tank System Installation

Experience a cutting-edge transformation in robotic cleaning technology with our state-of-the-art Raptor® Cleaning System. Catch this 30-second glimpse of the installation of a Raptor® system at the Hollidaysburg Rail Car Services’ facility. Witness precision engineering at work as our experts seamlessly integrate the system components, ensuring unparalleled efficiency and effectiveness in rail car cleaning. Embrace the future of “No Entry” tank cleaning with us, where Safety and Technology meet.

<iframe width="560" height="315" src="https://www.youtube.com/embed/Kp1m-2rzl94?si=E4v2P_7uAoVVieDj" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

Effective Heel Removal

The Raptor® Tank Cleaning System removes a broad range of materials and is built for most railcar environments including, hazardous, corrosive, food grade, flammable, and explosive. Download printable literature.

Flow Rate

0-260

GPM

Speed

Minutes

for total clean

Particle Size

4 inch

Max

Pressure

Up to 500

PSI

Superior Railcar Cleaning

Experience the superior railcar cleaning services at our Durant, Iowa and Richardton, North Dakota facilities, operated by Raptor® Tank Cleaning Services. Our Durant facility is strategically located on the Iowa Interstate Railway, connected to ALL Class 1 Railroads. Our Richardton, North Dakota facility is located on the BNSF. Both facilities offer unparalleled convenience and efficiency for your railcar cleaning needs.

Key Features of our facilities:

- State-of-the-Art Equipment: Our facilities are equipped with cutting-edge Raptor® Tank Cleaning Systems, ensuring the safest, most efficient, and effective cleaning process for railcars.

- No Human Entry: With our advanced robotics and automation, we eliminate the need for human entry during the cleaning process, prioritizing safety and minimizing risks.

- Environmentally Friendly Practices: We offer sustainable cleaning methods, including the reuse of the tank's original liquid as a cleaning solution, minimizing environmental impact and reducing costs.

- Efficient Turnaround: Our streamlined processes ensure fast turnaround times, returning your railcars to service in days, not weeks.

Trust Raptor® Tank Cleaning Services for comprehensive railcar cleaning at either of our facilities, delivering unmatched quality and efficiency.

Turn large heels into large profits.

Contact one of our experts to get started!