Raptor® Bristol Tank Cleaning System

Raptor® Bristol Units

Remove Heavy Deposits Fast with Bristol Tank Cleaning Systems. Cut and flush deposits from inside tanks, reservoirs, and process areas quickly and efficiently. Improve clean-out speed and safety. Recover valuable materials.

Features

Repetitive, Programmable, Controlled Jet Cleaning

Fast Cleaning

Raptor Bristol Tank cleaners removes heavy deposits of sludge from the bottom of railroad cars, typically in a quarter of the time used by manual cleaning methods.

Convenient Operator Control

Simple control valves provide independent manual or full automatic operation of each axis, plus adjustable motion speed control. Calibrated rods indicate nozzle position.

Program Control

Separate control assembly for remote, protected mounting. Safe air to oil drive, twin axis program control.

Independent axis controls with calibrated nozzle position indicators.

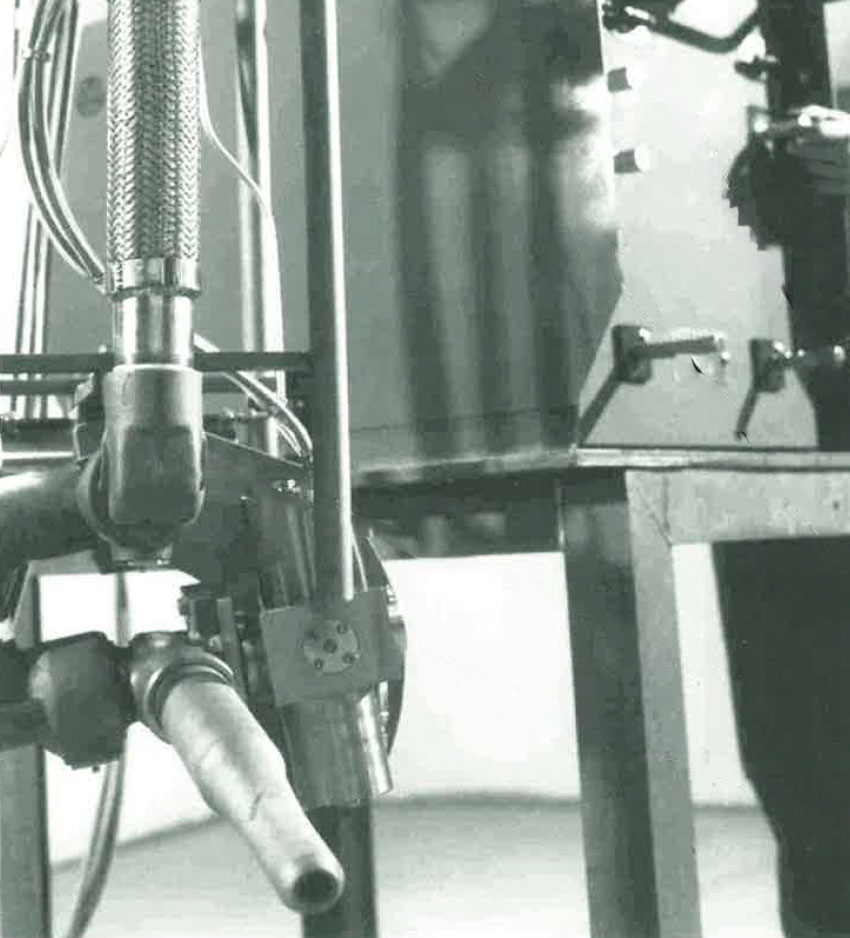

Nozzle Assembly

Stainless steel and TFE construction for protection in corrosive and abrasive

applications.

Oil driven slave actuators move nozzle in simultaneous longitudinal and transverse motion to control impact of jet stream.

Model M -7

For Concentrated Jet Cleaning the Automatic Way

The Bristol M-7 Cleaner uses a high-pressure stream of water, slurry or other solvent to automatically clean tanks, reservoirs, or similar difficult to reach areas. On command from the program control, the nozzle directs a concentrated jet stream in a pre-set pattern to cut, dissolve and flush deposits out of the tank discharge or drain port. It handles up to 250 gallons per minute at pressures up to 250 p.s.i., removing gypsum, clay, calcium carbonate, acid crystal, or similar precipitates without disturbing the tank or its lining. In addition, the M-7 Cleaner can help you recover valuable acids, fats, oils or other materials left in tanks. Empty weights of transport cars can be reduced, saving on return charges.

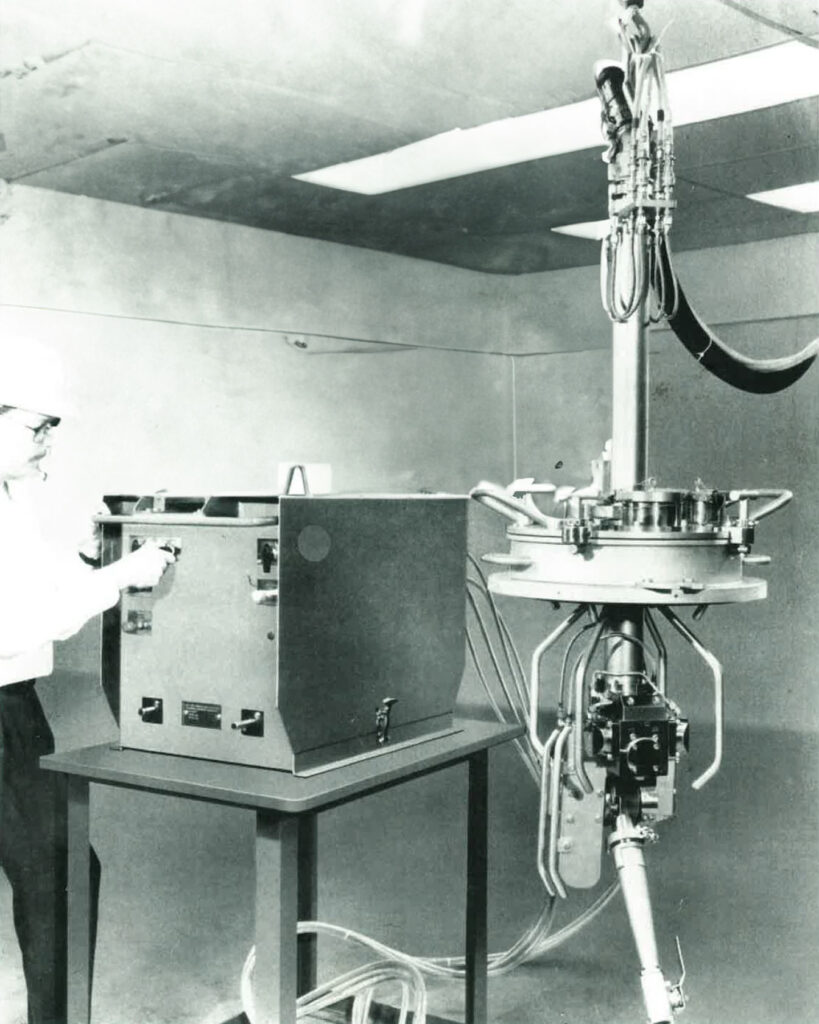

One Man Operation

With a light hoist, one man can easily position the nozzle assembly onto a car manway or other tank opening. The nozzle position is always indicated on the program control. Thus, the operator knows where the nozzle is pointing at all times and can avoid the hazard of looking into the tank interior. Manual valves also allow him to do quick remote spotting of nozzle position in order to blast open a drain or move to the starting point.

Design Features

The standard M-7 System includes a nozzle assembly, mechanically programmed control and connecting hoses. As a protection against corrosive atmospheres and solvents, all wetted metal parts are made of 300 series stainless steel.

Compressed air is used as the power source for improved safety, converted to hydraulic force to drive the nozzle in a controlled sweeping pattern across the length and width of the tank. Speed and distance of nozzle movement are regulated by a hydraulic master-slave circuit that allows independent adjustment of arc travel and speed in each axis. An interchangeable cam automatically adjusts the longitudinal speed to provide effective cleaning time at longer stream distances. Thus, the jet cleaning force can be directed where needed and for the exact length of time that produces the most efficient cleaning.

Model M-8A

Available for Full Diameter Cleaning

Model M-8A delivers a speed and position controlled jet stream for cleaning all interior surfaces of tank cars or similar containments. M-8A Control provides cam-following speed control on both axes. When tank top and side walls require effective jet-cleaning, look to the Model M-8A. Additional information on request.

Series TC-N1 Tank Cleaning System

Washes Highway Trailers or Railcars, Confines Fumes and Spray

The TC-N1 Tank Cleaning System efficiently removes deposits from highway trailers or rail tank cars using the proven jet-cleaning technique employed by other Bristol tank cleaning systems. The TCN1 features a sealed hatch mounting design that contains fumes or spray as the single jet-stream cuts hazardous deposits from the bottoms of trailers or rail cars. The system handles up to 250 gpm of wash solvent at pressures up to 250 psi to flush deposits out of the tank bottom drain. Slurries with heavy solids concentrations and corrosive liquids can be used for effective washing because the 1 ½ inch stainless piping is completely separate from the nozzle positioning actuators.

Design Promotes Efficient Cleaning

The TC-N1 Nozzle directs a concentrated jet-stream against deposits in the lower half of the tanks. Driven by rugged hydraulic actuators, the nozzle moves at a controlled speed across the length and width of the deposits, blasting them into a flowing slurry for gravity discharge. A carbide brushing in the nozzle tip resists wear, while a valve on the discharge prevents dripping of potentially hazardous materials. The TC-N1 Nozzle also offers the option to tilt 15° to either side of vertical. This allows the jet stream to clean behind vertical pipes in the tank. The height of the trunk section adjusts to accommodate different size tanks.

Control Programs Nozzle Movement

The Model C7 Control uses safe compressed air input, converted to precise oil-hydraulic pressure to drive the twin axes at adjustable, repeatable speeds. Speed and distance of each axis movement is independently adjustable.

Turn large heels into large profits.

Contact one of our experts to get started!